Textile Stenter Manufacturing and Assembly by Saben

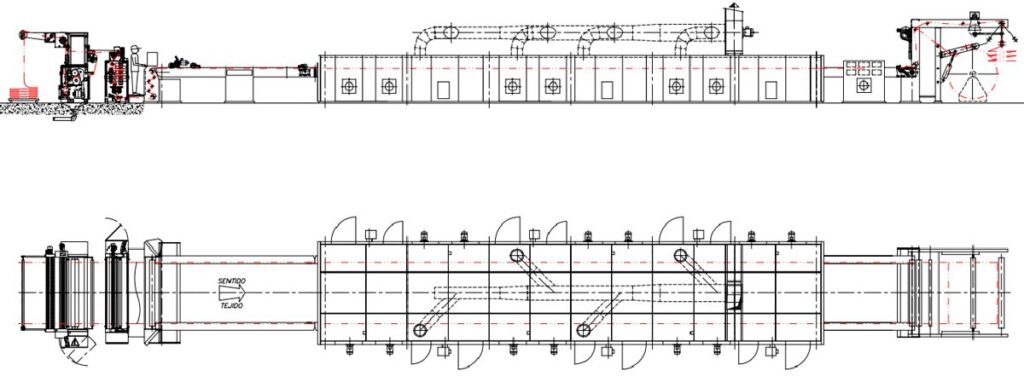

The Saben Stenter offers top of the range quality at a good price. With European fabrication and a unique design that achieves optimal stretching, drying and thermosetting that industry fabrics and textile finishing machines require in the finishing process. The precision in the control and adjustment of the variables involved, automation, and low-maintenance are all details that characterise a Saben Textile Stenter.

Benefits of a Textile Stenter

- Precision, reproducibility and uniform distribution in the degree of drying and thermosetting.

- Very economical energy consumption.

- Full automation.

- Robust design and low-maintenance.

Installation of Textile Stenter with Saben

Personalized Advice

We offer technical consultation and support to configure the stenter finishing line to best suit the specific needs of each client depending on the type of fabric processed, the required production speed, on-site location and positioning and any additional resources necessary.

Bespoke Designs

Specialised Manufacturing

Integrated Assembly

A once labour intensive task now can be adapted to a modern reality.

We carry out the installation of the stenter, fine-tune it and prepare it, ready to start the process it was designed for.

What type of Stenter do you need?

- Highly qualified and professional staff.

- Honest prices and fixed quotes.

- 100% satisfaction guaranteed

Technical Specifications and Advantages of the Saben Textile Stenter

- Machine Speed: 3.5 to 70m/min.

- Working Width: On request of client demands.

- Highly effective thermal insulation panels.

- Minimum energy loss.

- Environmental efficiency.

- Easy access to internal components for maintenance.

- Robust design of elements requiring low-level maintenance.

- Programmable and automated lubrication of chain and sliding blocks.

- Independent width adjustment spindles per field for weft yarn shrinkage.

- Nozzles with plug-in system for easy cleaning

- Automatic covering of infeed and outfeed slits to suit fabric width.

- High performance radial fans with direct attack on motors providing highest drive capacity with uniform air distribution and air quantity.

- Precision, reproducibility and uniform distribution in the degree of drying and thermosetting.

- Regulating flaps in front of the nozzle boxes allowing top and bottom airflow to be continuously adjusted.

- Removable filters allowing for cleaning and maintenance without stopping machine.

- Available heating types: direct gas, indirect gas, thermal oil, steam and electric.

Request a quote today

Frequently asked questions about Stenter Machine

What is a textile stenter?

How long will fabrication take?

How much does a stenter machine cost?

What should I consider when choosing a stenter?

Why choose Saben Textile?

Because in industry, decisions made mean an investment relies on payback over time, in some cases years. Finding attainable solutions are in most cases varied.

We can help you find the best possible solution so you can get started with your project as soon as possible.